| |

|

| |

|

| 1 Piercing Methods |

| 2 Mannesmann Brothers' Discovery during Polishing Bars |

| - A crack in the middle of the polished bar |

| 3 Mannesmann Piercing |

| |

|

| 1 Piercing Methods |

| |

| The piercing is to make a hole on the solid material. If you consult it to the dictionary, you may see the piercing methods about the body piercing for earrings, because many people are interested in the body piercing. However, it means to make a hole to anything. |

| |

| The holes in the ancient stone moneys might be done with the steep stones. Some monks might cave the big rocks with steel chisels in order for people to go to the other side. In this article, I would like to explain the piercing of the metals. There are many ways to pierce the metals by removal of the unnecessary parts by using gas burners, by melting metals with arc discharging, and by drilling. Even highly pressurized water can make a hole on the metal. In these cases, the metal of the hole is lost. Another way, which does not generate lost metal, may be to push the metal with a hard bar. In this case, you can save the scrap metal, but the bar may need frequent repair of change. There is the third way. It is to make a hole by rubbing. |

| |

|

| 3 Mannesmann Brothers' Discovery during Polishing Bars |

| |

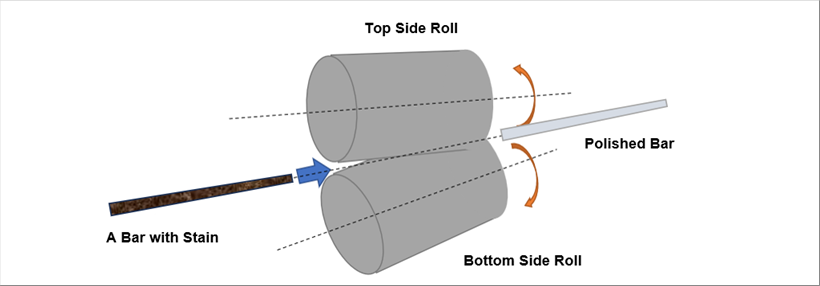

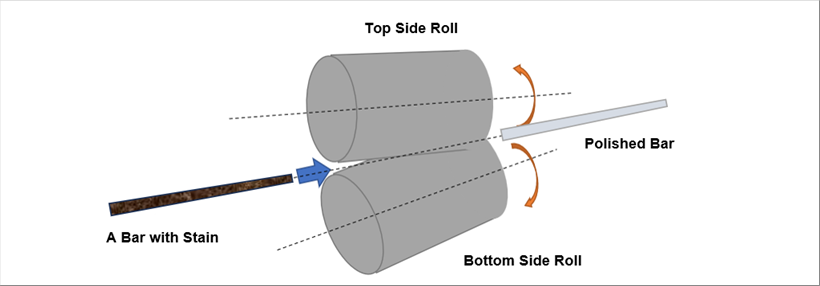

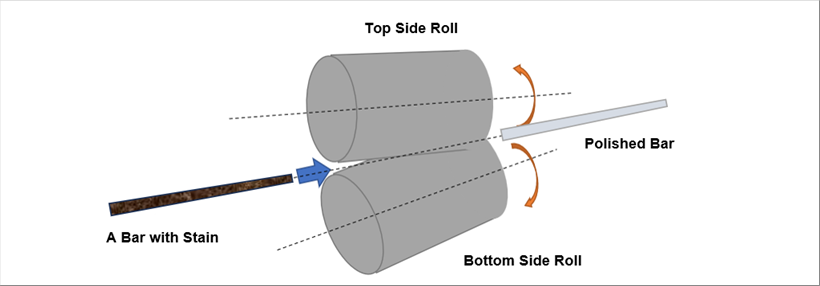

| The Mannesmann Piercing is to make a hope by rubbing the metal. Their job was to polish the metal bars. They faced a problem. It was a hole in the middle of the bars. In certain conditions of the polishing, they faces the holes. It was really amazing that they discovered a new piercing method after a lot of efforts. I would like to explain what is the Mannesmann Piercing without difficult formula. |

| |

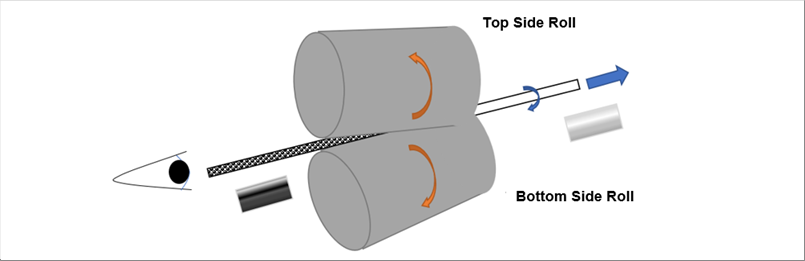

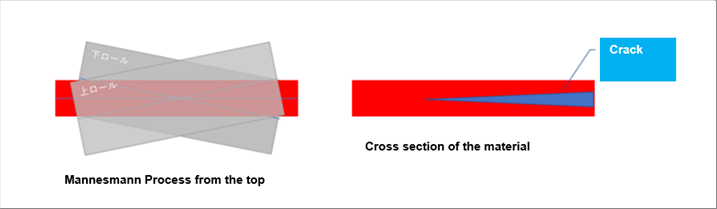

| The brothers' way of polishing bars is as following. A pair of the rolls are set with some angles. The rolls rotate with some load on the bar. Thus, the rolls rub the bar, which is moved from the entry of the rolls to the exit. The stain on the bars can be removed by the rubbing. |

| |

|

| |

| The angled pair of rolls to polish the bar is more efficient that that of the manual cleaning. It is good for the mass production with lower cost. |

| |

|

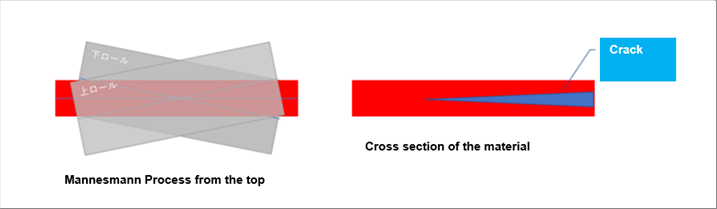

| - A crack in the middle of the polished bar |

| |

| The slight touch of the rolls might be enough to obtain the polished surface when the stain is thin and so even. However, the actual one is uneven, some are thick, some are strongly attached to the bar. The bar might have dents where full of stain. In order to polish such bars, the more load might be necessary. |

| |

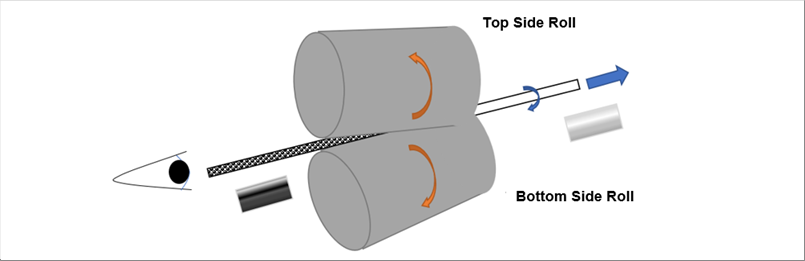

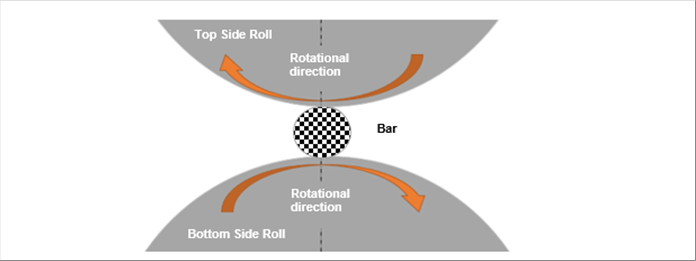

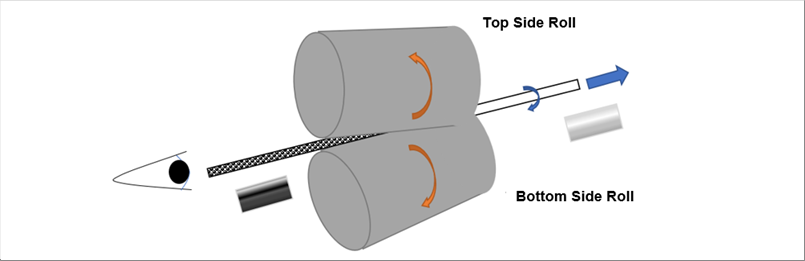

| In order to see the contact areas between the rolls and the bar, it may be a good idea to see from the entry (or exit) side of the rolls. |

| |

|

| |

| The following picture shows the cross section of a contact area from the entry side or the rolls. The right one shows the enlarged view. |

| |

|

| |

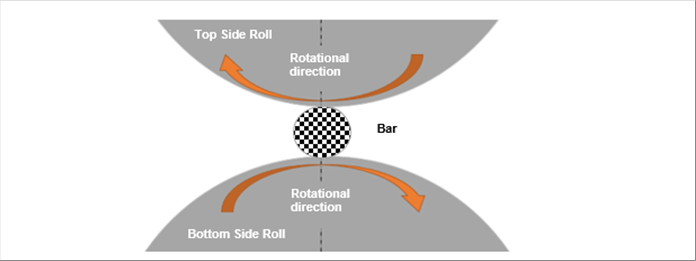

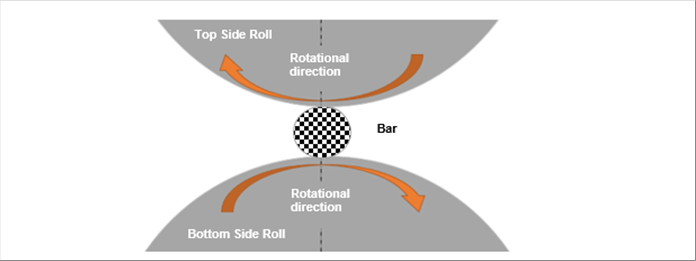

| The load of the both of the rolls is applied on the bar. Therefore, the bar is distorted due to the compressing load. At the same time, the bar is rotating. Therefore, the compressed surface becomes free from the compression as it rotates. After the half rotation, the surface is compressed again then again the compression becomes zero (0). The following picture omits the rolls to focus on the inside area of the bar. |

| |

| The cross sectional shape is like a oval due to the load of the roll. The horizontal outside surface of the oval is free from any load. As per the physical laws, the directions of the distortion and the force coincide; however, the outsides surface of the horizontal direction has no load. Therefore, it is considered that the tensile force is applied at the center of the bar. |

| |

|

| |

| The white area indicates the contact area of the left end picture. As the bar rotates, it also rotates. The square in blue color is picked up for us to focus, because a crack sometimes is seen under certain conditions. The following picture shows the square. For the easy understanding, the square is fixed and the load rotates around it. |

| |

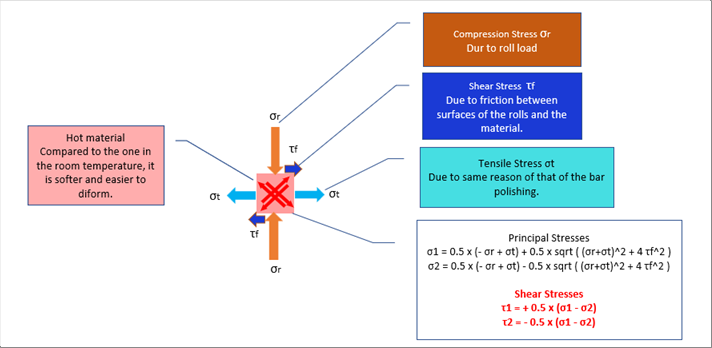

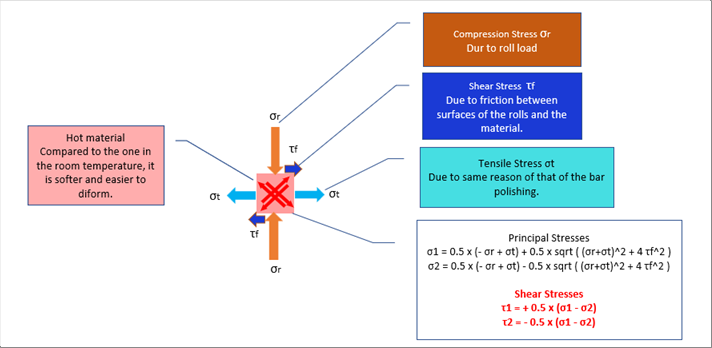

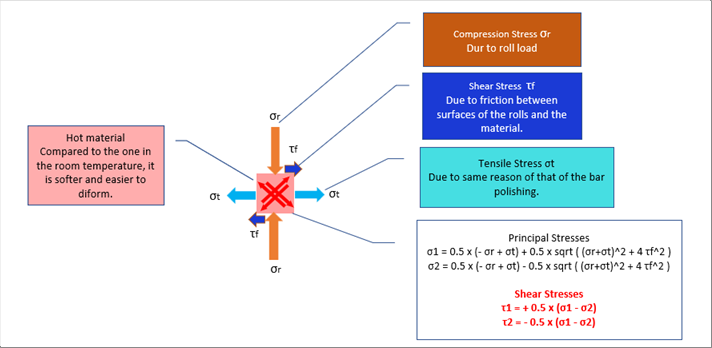

| It does not crack due to the compression stress, but it cracks due to the tensile one. In addition to the compression and the tension stresses, the shear stress, which is equal to the average values of those two (2), is generated at forty five (45) degrees from the stresses. |

| |

| In addition to the tensile stress, the shear stress is another factor or the cracking. The following picture illustrated the stress condition of the bar polishing. |

| |

|

| |

| The following equation indicates the shear stress. |

| |

|

| |

| Let's continue. Is there any effect of the rotation of the roll? |

| |

|

| |

| The cross section of the bar is like a small oval. Therefore, a part of the rotaional force may act as the shear stress, which is applied to the bar by the friction between the bar and the roll surfaces. However, it is considered small and it may be ok to omit it. |

| |

| As said in the begenning of the article, they faced the crack in the middle of the bars when they polishded the bars. It is believed that the shear stress in the middle of the bar incurred the crack. |

| |

| The crack is harmful for the polishing of the bars; however, Mannesmann brothers found the possibility to apply the problem as a new piercing method. They made a lot of effort and finally invented the Mannesmann Piercing method, which many of seamless pipes manufacturing companies are using today. |

| |

|

| 3 Mannesmann Piercing |

| |

| The temperature of the Piercing process is about 1200 degrees C. The steel is very hard at the room temperature and hard to pierce. However, it becomes soft at that temperature. Therefore, when load is applied to the hot metal, the material easily crosses the limit of the elasticity and shows the permanent deformation. (Please refer the metal plastic deformation theory for detail.) |

| |

| Due to the high temperature, the material cracks easily. The following picture shows the condition of the stresses. |

| |

|

| |

| The rim of the crack is thin, and therefore, it is easy to be cooled. Due to the lower temperature than the rest, once it cracks, the cracked rim cannot perfectly re-melt to the rest of the material. Therefore, the crack remains in the inside surface of the pipe. |

| |

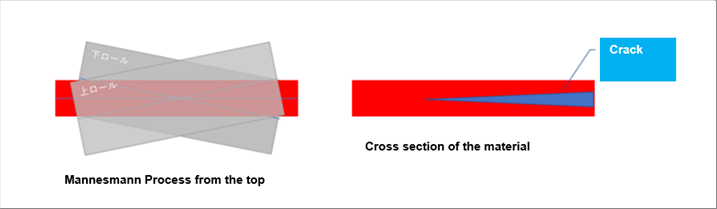

| The following picture shows the illustrated condition when we stop the piercing process in the middle of the rolling. Whe we use only the rolls, The crack occurs in the middle of the material, and it remains after the rolling. The inside surface of the pipe is full of cracks and it is necessary to improve it. |

| |

|

| |

| In order to improve the inside surface condition, the point of the Mannesmann Piercing process is to use another tool in the middle of the bar. The tool is set at the position where it begins cracking. The following picture introduces the typical layout of the Mannesmann Piecing method. The additional tool is illustrated in black color. Thanks to the additional tool, you see almost no crack inside and can enjoy the good inside surface. The work force, which is to be applied to the tool, is much smaller than that of without Mannesmann Piercing method, because the material is about to crack. |

| |

|

| |

| Thanks to the additional tool, the inside surface problems were dramatically improved. They finally completed the Mannesmann Piercing Process, which is utilized in all over the world as of today. |

| |

| The additional tool is called "Plug", which is like an ammunition of the cannons. The plug is supported by a bar. All of these components are controlled to obtain the good inside surface quality and necessary wall thickness. |

| |

| Author: T. Oda |

| Preparation in Excel, automatic html / css generation by the "excel2web". |